Professor Jun Du, Reader Luciano Battista and Dr. Oleksandr Shepotylo (Aston University)

Faced with the challenge of climate change, and the growing need for sustainable business practices, it can often be hard to know where to start. In this guide, InterAct researchers examine the critical role of global value chains for the future of UK manufacturing, through the case study of the electric vehicle sector.

The UK automotive industry stands at a crossroads, facing a rapidly evolving landscape driven by the global electric vehicle (EV) revolution. While EVs offer a pathway to a greener and more sustainable future, the challenges of global value chain (GVC) dependencies, rising material costs, and competitive industrial policies present formidable hurdles. InterAct research has delved into these dynamics and outlines strategies for positioning the UK as a leader in sustainability-oriented manufacturing.

Industry in transition

Recent developments underscore the urgency of action. In November 2024, Stellantis announced the closure of its Vauxhall plant in Luton, resulting in 1,100 job losses. This follows Ford’s decision to cut 800 UK-based positions and Nissan’s global reduction of 9,000 jobs, with major potential implications for its UK operations.

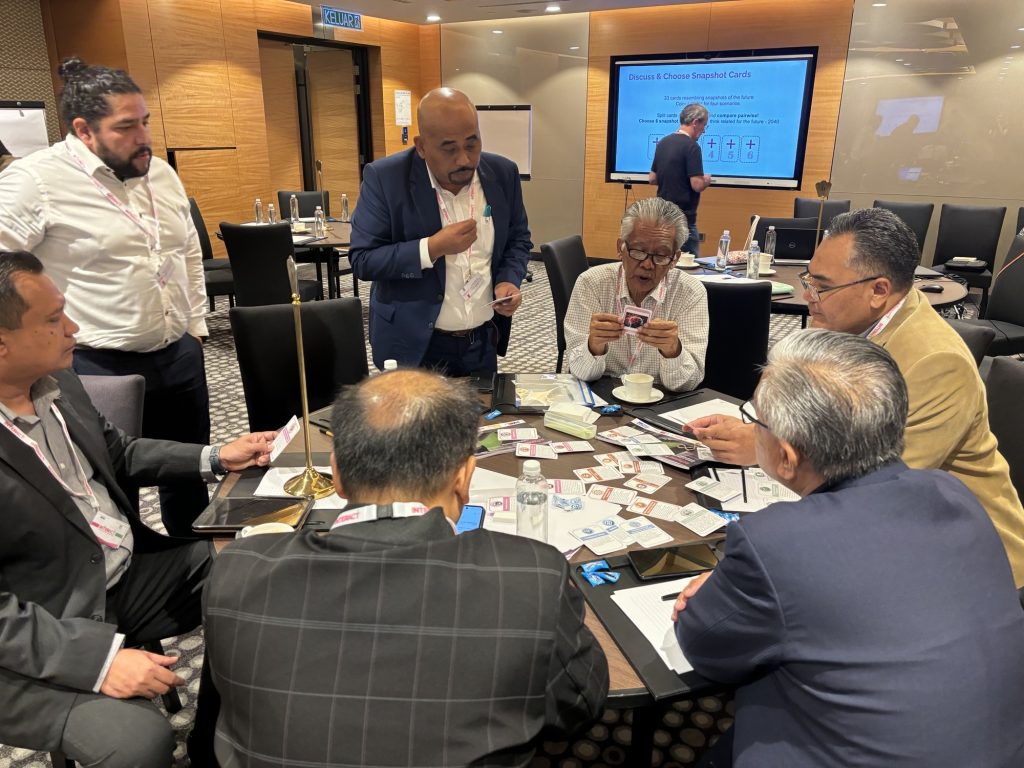

These challenges reveal a broader issue: Europe’s historical dominance in the automotive sector is under strain, and the UK must adapt to remain competitive amidst shifting supply chains and mounting global competition. Nor is this unique to the automotive sector, with many organisations and governments in developing economies seeking technology transfer and more equal partnerships as a requirement for access to markets or local production. Explored in our global research missions, the rapid pace of advancement in manufacturing across countries like Singapore, India and Malaysia, highlights the need for the UK to evolve to compete.

The changing EV landscape

The transition from internal combustion engine (ICE) vehicles to EVs, driven by technological advancements, environmental awareness, and significant policy support, is reshaping not only the automotive industry but also the intricate web of GVCs that underpin EV production.

Since 2010, the cost of lithium-ion battery packs has plummeted by 89%, making EVs increasingly competitive with ICE vehicles. EVs now account for a substantial share of global passenger car exports, growing from 4.3% in 2017 to 27.6% in September 2024. This growth has been bolstered by government incentives, such as tax credits and investments in charging infrastructure, and by tightening emission standards.

Germany and China lead the EV sales in export value and quantity respectively. UK-made EVs, while primarily destined for EU markets (accounting for 68% of exports), face pressure, despite being delayed, to comply with rules of origin (RoO) requirements under the EU-UK Trade and Cooperation Agreement (TCA). These rules necessitate higher regional content in EVs and batteries, complicating the supply chain landscape.

With the challenge of where to locate manufacturing, new opportunities are arising through the reshoring or ‘right-shoring’ of production, with localised manufacturing offering improved resilience against global supply chain shocks such as pandemics, conflicts or logistical disruption. Locating manufacturing closer to the consumer base also offers the potential to significantly reduce the carbon footprint of supply chains due to significantly shorter transport links.

Three key trends shaping the future

- EV adoption is growing, but steady policy is crucial

In September, electric vehicles (EVs) accounted for 27.6% of car sales across 15 major markets, marking a 7.6 percentage point increase year-on-year. The UK ranks fifth globally in EV adoption, underscoring its potential as a leader in this transition. Electrification is the future, but progress hinges on a stable, predictable policy environment that encourages investment and innovation. It is therefore essential that manufacturers make their voice heard, with collective messaging to government and policymakers that can cut through the noise, encouraging a clearly articulated vision and strategy.

- Europe is catching up in battery production

While China continues to dominate the lithium-ion battery market, European nations such as Poland, Hungary, and the Czech Republic are emerging as key exporters of EV batteries. Meanwhile, the Inflation Reduction Act in the US has spurred the growth of US electric vehicle innovation and production. In the face of such major competition, the UK should seriously consider aligning closely with EU supply chains to potentially enhance resilience and competitiveness, ensuring the automotive sector remains integrated into global markets. This consideration is especially relevant in light of recent EU legislation surrounding traceability and digital product passports, explored in an InterAct funded research project.

- Supply chains will determine future winners

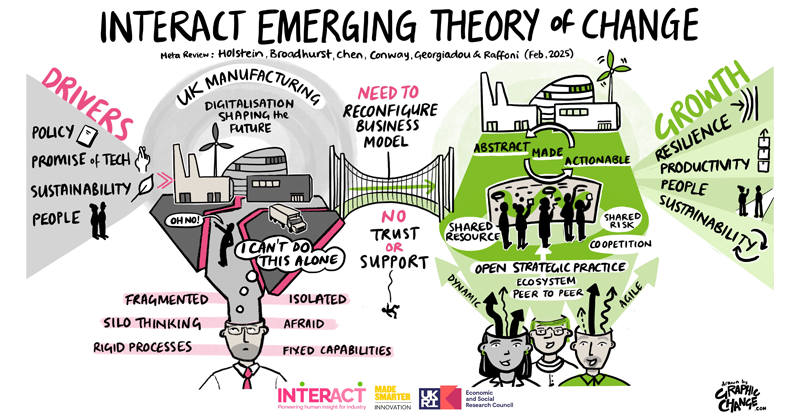

Success in the automotive industry increasingly relies on building efficient and adaptable supply chains, not just manufacturing the best vehicles. This requires collaboration, investment, and strategic vision—elements that are difficult to achieve without systemic support. InterAct’s ‘Scenarios 2040’ work from researchers at Loughborough University has highlighted the essential importance of taking a full ‘ecosystem’ approach to the future of the sector, with manufacturers working with suppliers across their supply chain to determine the most viable and beneficial future for everyone.

A moment for strategic decision-making

The UK manufacturing sector is at a pivotal moment. Sustaining its position in this high-stakes global competition will require visionary leadership, robust policy support, and alignment with broader industrial strategies. The alternative—neglect or fragmented efforts— is likely to result in a gradual decline of one of the UK’s historically significant sectors.

If the UK Industrial Strategy is to back industries such as automotive manufacturing with bold action instead of pivoting decisively towards other emerging opportunities, then policymakers and manufacturers need to explore and adopt strategic recommendations. In the case of the automotive industry shift to electric vehicles, these are:

- Enhance domestic capabilities

- Invest in local battery production facilities and recycling initiatives to reduce dependency on imports and align with RoO requirements.

- Promote innovation in battery technology to improve efficiency and lower costs.

- Optimize trade policy

- Negotiate flexible trade agreements that account for the complexities of GVCs.

- Strengthen partnerships within the EU to ensure seamless access to key markets.

- Strengthen supply chain resilience

- Diversify sources for critical materials to mitigate geopolitical and market risks.

- Establish regional partnerships to secure stable supply chains for EV production.

Charting a Path Forward

The success or failure of the UK manufacturing sector over the next few decades hinges on its ability to adapt to the changing global landscape. By addressing critical dependencies and fostering innovation, the sector can leverage the opportunities presented by the green technology revolution. With strategic investments and policy alignment, the UK can solidify its position and push towards a bright manufacturing future.