Overview

The manufacturing sector is a vital component of most economies, which leads to many cyberattacks on organisations, whereas disruption in operation may lead to significant economic consequences. Adversaries aim to disrupt the production processes of manufacturing companies, gain financial advantages, and steal intellectual property by getting unauthorised access to sensitive data.

Access to sensitive data helps organisations to enhance the production and management processes. However, majority of the existing data-sharing mechanisms are either susceptible to different cyber-attacks or heavy in terms of computation overhead.

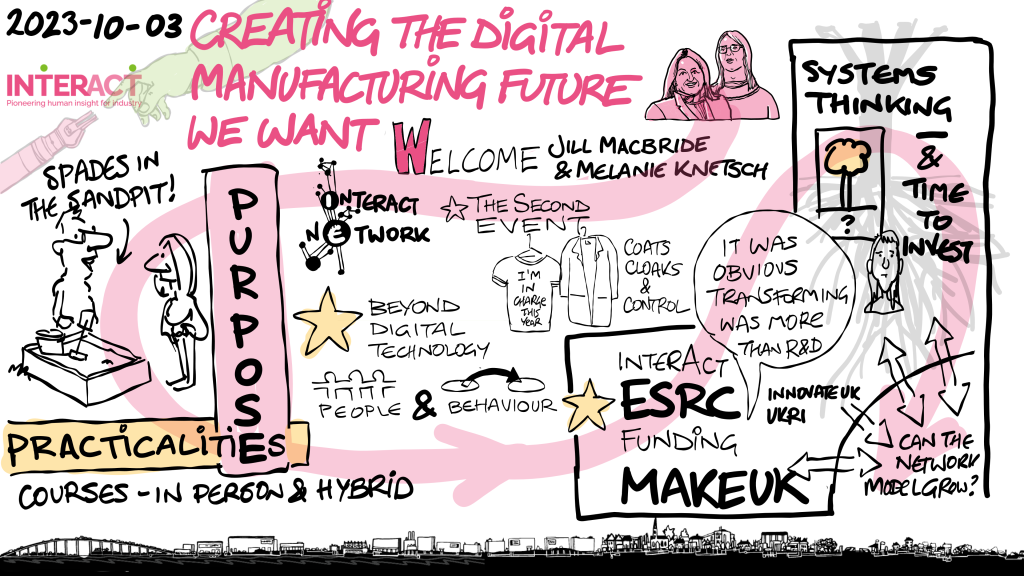

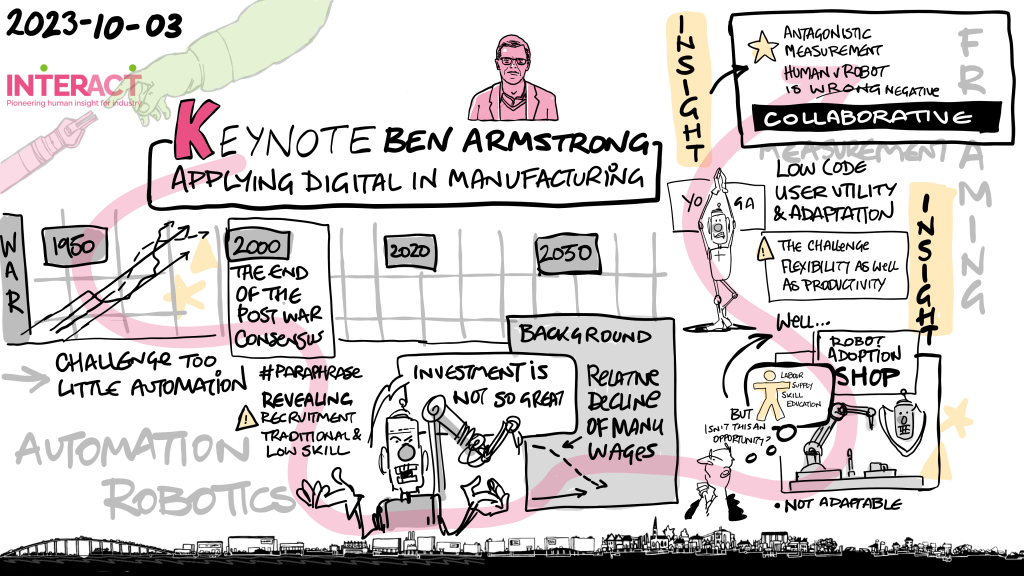

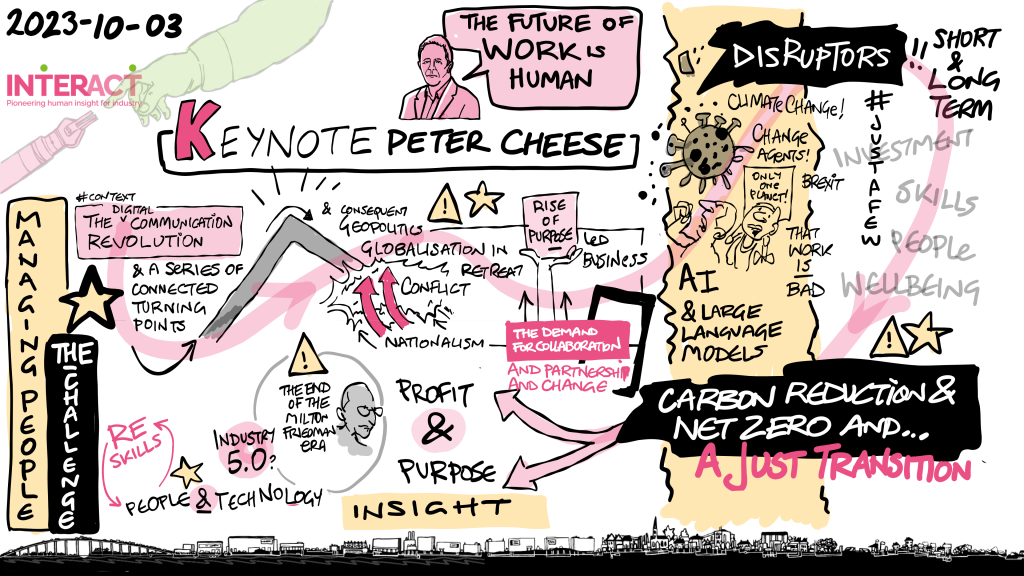

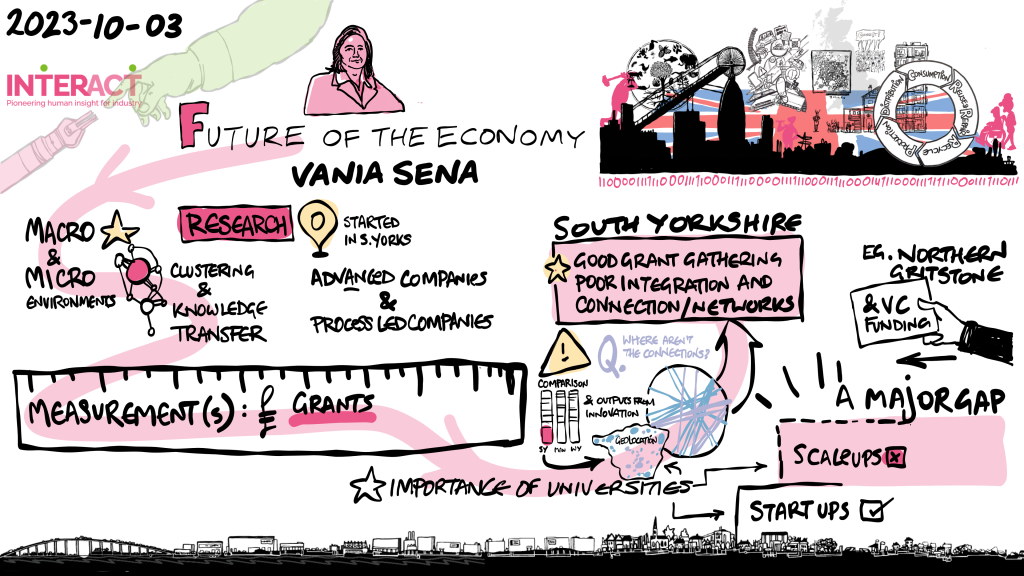

This project worked with manufacturing industry representatives, digital technology providers and cyber-resilience centres across the country to develop ways to manage behavioural change to ensure cybersecurity improvements, whilst using psychological models to plan new ways to adapt to these changes.

Digital cyber security tool

Arising from the results of this research, the team has developed a free to use online cyber security tool which allows you to assess the cyber-security readiness of your organisation to understand what areas require your attention. This valuable tool offers manufacturers the chance to effectively examine their own cyber security preparedness and enable the safe implementation of new digital technology into their workplace.

Conference paper – Local Differential Privacy-Based Data-Sharing Scheme for Smart Utilities

In the team’s conference paper, a privacy-preserving data-sharing scheme for smart utilities is proposed. First, a customer’s privacy adjustment mechanism is proposed to make sure that end-users have control over their privacy, which is required by the latest government regulations, such as the General Data Protection Regulation.

Secondly, a local differential privacy-based mechanism is proposed to ensure privacy of the end-users by hiding real data based on the end-user preferences. The proposed scheme may be applied for different industrial control systems, whereas in this study, it is validated for energy utility use case consisting of smart intelligent devices. The results show that the proposed scheme may guarantee the required level of privacy with an expected relative error in utility.

This work was carried out by Dr. Bruno Bogaz Zarpelao (State University of Londrina, Brazil), Veniamin Boiarkin, Professor Muttukrishnan Rajarajan, Professor Rajkumar Roy and Professor Katy Tapper (City, University of London, United Kingdom). This work was supported by the UKRI Made Smarter Innovation Challenge and the Economic and Social Research Council via InterAct [Grant Reference ES/W007231/1].

For further discussions or potential applications/collaborations, please contact Muttukrishnan Rajarajan.