Overview

Working from home, or telework, has been rising in the past 20 years, but large-scale adoption of this practice was never really embraced by the majority of UK employers. In March 2020, the COVID-19 pandemic ‘flicked a switch’ overnight, and all workers who were able to work remotely were compelled and facilitated to do so, through digital technologies.

Whilst many people who worked from home during the pandemic, many others found themselves with a lack of appropriate workspace, or experienced a sense of social isolation. As the pandemic subdued, patterns of work have evolved into more complex patterns of hybrid working.

The benefits and disadvantages of working remotely remain in this dichotomy of place – home or the office – yet new workspaces, such as coworking spaces (CWSs) offer a third option. Indeed, the growth of coworking spaces has grown significantly across the world since the pandemic, not only in cities, but also in the suburbs, towns and rural villages.

Other countries (across Europe and the USA) have recognised the potential of CWSs, to help deliver economic growth and develop places beyond their core cities. They have begun to develop explicit policies to support remote working from these places. However, there is a noticeable absence of this type of discussion in UK policy and the question is, why? Are they not popular in such areas of the UK, are they different to city-based CWSs, in what ways? What are the implications for the areas they are located in?

Our pilot study of CWSs in a number of provincial areas in England examined what CWSs in these areas look like, what they do, what are their governance structures and the potential they hold for raising entrepreneurship and business growth beyond core-cities. We interviewed owners, managers and users of CWSs; Chambers of Commerce, local councils, local enterprise partnerships. We made observations of a variety of CWSs types, business models and identified the range of their activities they undertook to support their local areas. We listened to how they were faring, their relationships with each other and other local bodies. Our findings are summarised in two reports. Whilst designed to sit as separate briefs, there is complementary in what they cover, and benefit from being read together.

The first report “The rapid rise of rural co-working in England: sharing experiences for mutual learning” is a briefing for industry. It identifies the activities undertaken across a range of CWSs and collates them to provide insights and suggestions to other CWS owners and managers about the best practices we observed, so that these might be considered by those who do not currently adopt them and strengthen the role of their CWS to its local economy further.

The second report “The potential of coworking spaces to stimulate local growth outside of major cities” is a briefing to local and national policymakers. It identifies more specifically, the contribution CWSs can make to various levels of community: the community within the CWS, the local business community around it, and the wider social community in which they reside. It also identifies areas in which the government could offer more support. The potential value CWSs bring to each level of community means they deserve to have greater attention from local and national policymakers as they grapple with how to stimulate local growth and prosperity across the UK.

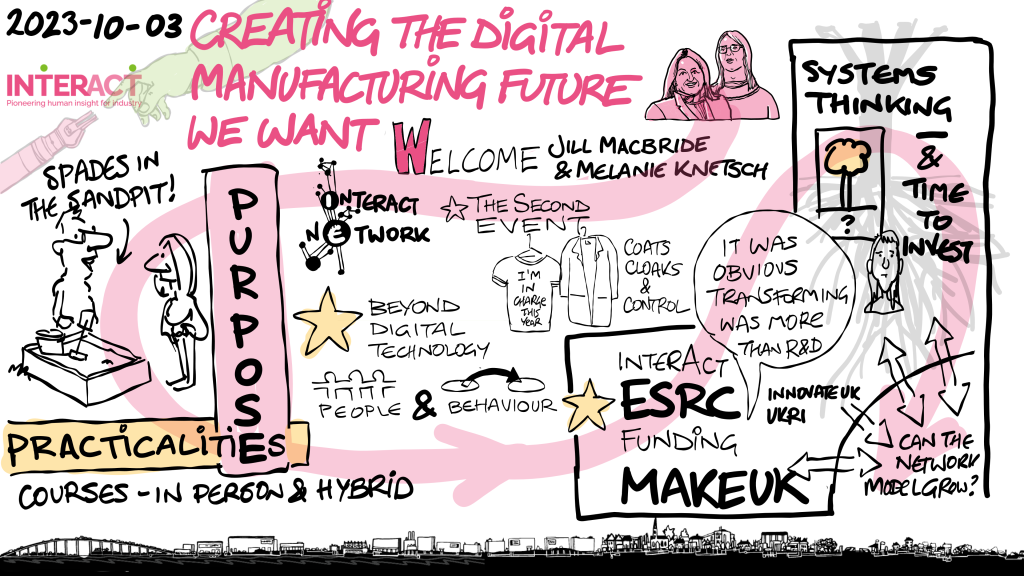

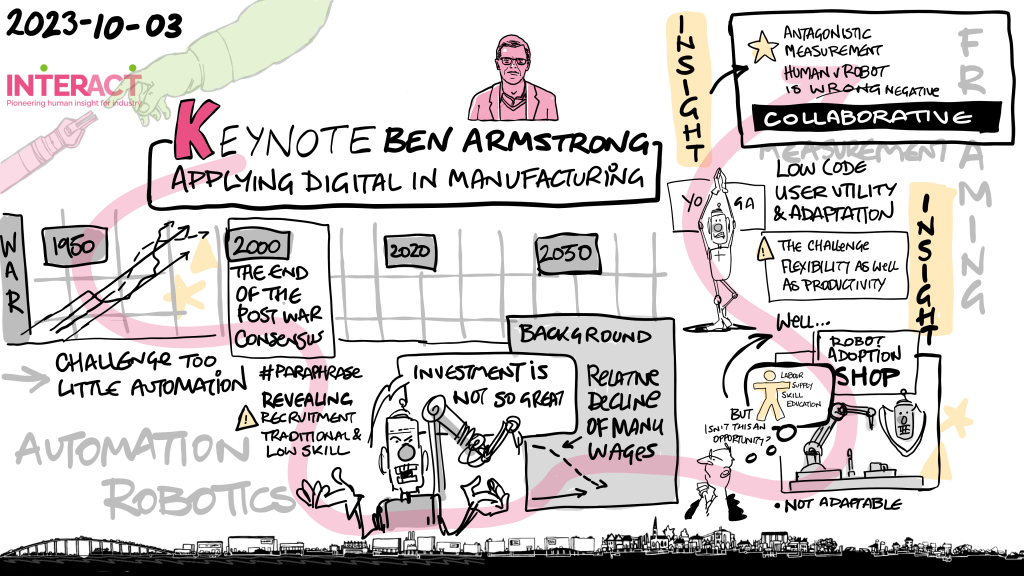

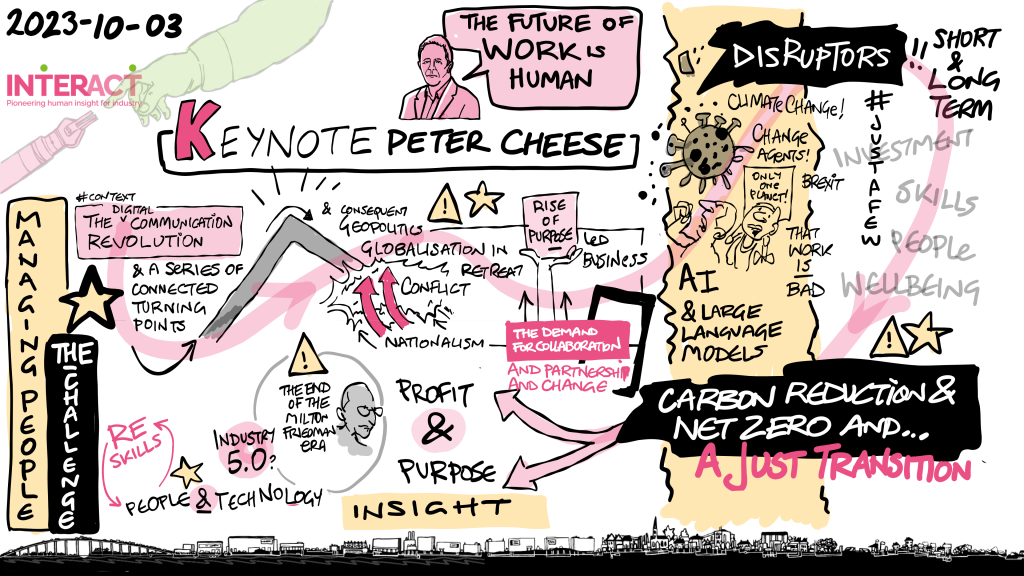

This research was conducted by Dr. Felicia M Fai, Dr. Mariachiara Barzotto and Professor Phil Tomlinson (University of Bath). This work was supported by the UKRI Made Smarter Innovation Challenge and the Economic and Social Research Council via InterAct [Grant Reference ES/W007231/1].

For further discussions or potential applications/collaborations, please contact Felicia Fai.