Acting to improve sustainability is increasingly important to forward-thinking organisations.

It is no longer sufficient to see sustainability as an ‘added extra’, distinct from the fundamental needs of a business. The motivation for changing an organisational view of sustainability may differ, but can include:

- playing a part in a progressive vision, value set, and culture

- as a tactic to appeal to customers

- responding to changing climate conditions to maintain access to essential resources

- ensuring regulatory compliance.

When we consider sustainability, we need to take a comprehensive view, examining not only what it is made of, but also where it comes from, and how it is moved from end to end. Piles of electronic waste or scenes of plastic discarded in the ocean are a testament to the environmental impact once a product has left your ownership.

International standards and regulations formalise the responsibility to act – through initiatives like the Greenhouse Gas (GHG) Protocol and its Scope 1/2/3 accounting for carbon, or incoming EU instruments like the EU Deforestation Regulation (EUDR) or Corporate Sustainability Due Diligence (CSDDD). Delivering your sustainability goals and future-proofing your business means taking action on your supply chain.

The struggle to survive – the problems of today and the challenges of tomorrow

The challenges confronting supply chain leaders are constantly growing:

- challenging business environment

- huge complexity and ‘permacrises’

- global, multi-tiered value chains

- pace of change in operations and regulations

- competing priorities

- lack of quality data and visibility.

With so many urgent priorities, it can be tempting to see the sustainability agenda as another just another complication to throw into the mix. Understanding the business’ place in a changing world and rewiring it to thrive there is a daunting prospect in a reality of short-term targets, annual results cycles, and returns to shareholders and investors.

The world of supply chain management is changing

Driven by these challenges, supply chain management is itself evolving. There has long been recognition that leanness and efficiency can equate to rigidity and brittleness. Relentless focus on profit, and therefore cost, reduces flexibility and pushes every actor in the chain to the brink, with catastrophic effects when a link breaks.

Covid-19, blockages in the Suez Canal, and forced diversions from the Red Sea are all highly memorable recent examples of this disruption. Conversely, some of the world’s most profitable companies have shared a common characteristic, being recognised for their ‘elite supply chains’. Amazon, Nestle, Apple, McDonalds, Scheider Electric, Colgate-Palmolive, and P&G all enjoy this distinction.

Business leaders are increasingly drawn from, or come to focus on, supply chains as a value generator and a business protector that can:

- Deliver extremes of customisation in the product range, packaging, and presentation, worldwide, on time.

- Provide ready substitutes to seamlessly switch to when faced with trade barriers, blocked trade routes, or a supply breakdown.

- Offer hyper-personalisation alongside operational excellence, with impeccable credentials on the provenance of materials.

Supply chain excellence is no longer just about getting the right product, at the right time, to the right place. It is also the ability to configure the chain to withstand volatility, be resilient, and support strategic goals.

What might the successful, sustainable supply chain-oriented companies of the future look like?

From short-term gains to long-term value

The first key consideration is what new strategies businesses are looking to adopt, in which the supply chain is a fundamental enabler. A good illustration is the automotive sector. For large manufacturers, value is usually delivered on the sale of a brand-new vehicle. However, many of these companies are now developing long-term lease and maintenance strategies – promoting long term value and paying for usage, rather than ownership.

This marks an important departure from a total focus on short-term performance goals, where there is little incentive to plan for longevity. As these business strategies change, these new products and services depend entirely on reimagining the supply chain from linear to circular; from a source of costs to a generator of value.

From mutual suspicion to targeted collaboration

As companies have sought to maintain their edge and provide fair competition, historically, meaningful collaboration has been challenging. However, organisations and coalitions are taking positive steps by pooling resources and information to demonstrate progress. For example, in fashion and apparel traceability platforms like Worldly, or the retail-oriented BRC Mondra coalition which focuses on automated life cycle assessments (LCAs).

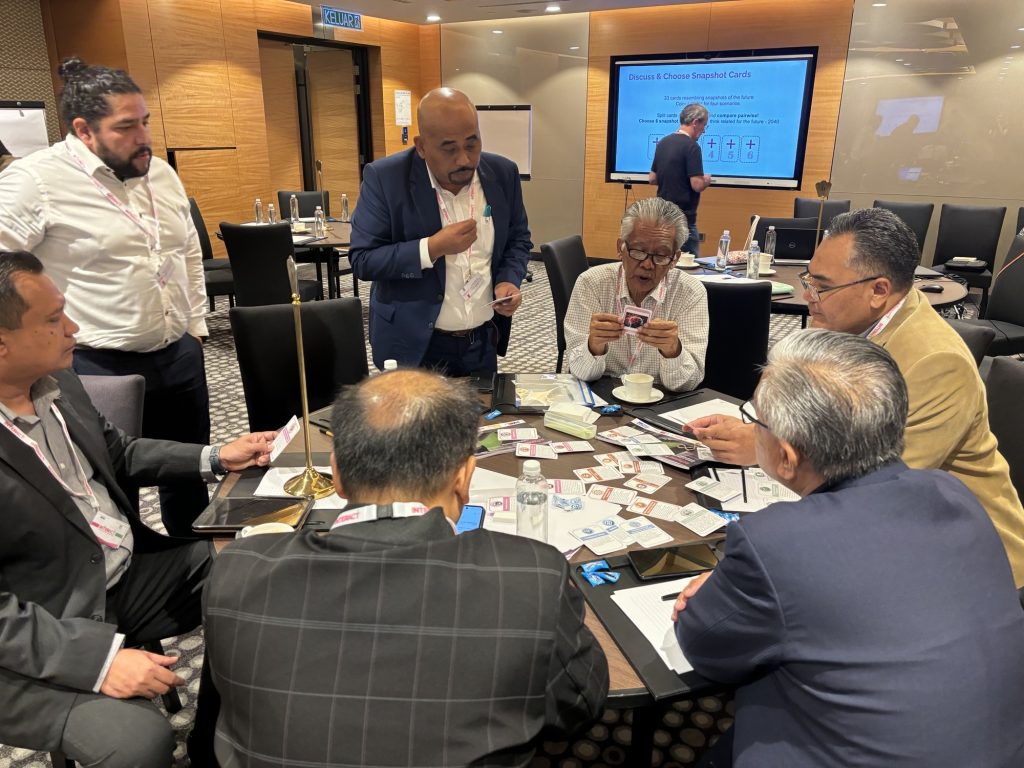

Developing staff capabilities for sustainability is rapidly becoming a key area for organisational training. Whilst, each organisation may face specific sustainability challenges, much of the basic knowledge required to address these challenges is common across sectors. Time and effort can be saved by pooling resources, with the added benefits of building connections, expanding collective understanding and setting consistent standards for providers across the chain.

From guarding data to promoting visibility

There is significant complexity in knowing what needs to be shared, transferred, or updated for different reporting or operational control requirements. Data, and the understanding of using it effectively, is increasingly jealously guarded. However, a purely transactional approach is counterproductive when success depends on effective collaboration with value chain partners. Proposed actions to decarbonise freight transport cannot be imposed suddenly by a customer to their logistics provider without incurring service impacts or indirect cost increases.

We need to move away from ideas of one-directional ‘supplier management’ towards meaningful, supportive partnership development. This approach builds in healthy interdependence, commitment and collaboration by design, with multi-year agreements and shared risk/reward contractual agreements. Rather than seeking to out-manoeuvre suppliers, successful businesses should try to align strategic goals for mutual benefit.

From demand-driven to demand-shaping

Consumer consumption patterns are at the heart of the sustainability challenge. Examples such as fast-fashion, with frenzied marketing stoking demand for inexpensive, often synthetic, on-trend products with a short lifetime that results in huge pollution and waste in landfill.

It is often said that the most sustainable product is the one you already have. But how can businesses respond to the challenge to sell less new products? Fashion brand Patagonia offer one good example, seeking to change demand by designing for longevity and offering a commitment to repairs. Even enormous e-commerce companies such as eBay are now offering free sales on second hand clothing in response to the growth from Vinted and other similar platforms that threaten disruption.

What does this mean for the sustainability agenda?

Meeting your business goals means achieving your supply chain goals.; and the evolution of supply chains necessitates putting sustainability challenges and opportunities at the heart of your strategy. We know that the climate crisis will get worse before it gets better, as recent and future mitigating efforts will have a delayed impact, but we shouldn’t let that discourage taking action. We are already seeing the impact of climate change on supply chains, so building in these considerations is also an essential part of creating resilience. As supply chains operations are reinvented from efficiency management to the development of resilient value creation, they can and must incorporate sustainability to shape the business of tomorrow.

This article was published by Loughborough University, read the original version here.

About the author

Judith Richardson leads the sustainability practice at management consultancy, Argon & Co UK, working with clients to operationalise their sustainability strategies, turning long-term visions into tangible action that makes a difference.