Russell Watkins (Sempai)

The Interact tagline was carefully crafted when Made Smarter and ESRC stumped up the money to make this network a reality. That tagline being: “pioneering human insight for industry” with the spoken aim to create a “network that aims to bring together economic and social scientists, UK manufacturers, and digital technology providers to address the human issues resulting from the diffusion of new technologies in industry”.

Yes, yes and yes again – this is what drew me to interact in the first place. It makes perfect sense when you think about it; in our factories, to make things, you need to bring machines, materials, and a method of doing it together with people. People are the glue that make the 4Ms work in harmony. And yet, walking the halls of Smart Factory conferences – the exhibitor wares on show are 95% things or data.

IoT, Sensors, robots, cobots, AI and data analytics are all critical, in tandem with people. We need to concurrently invest in skills to get the best out of these innovations, especially if we want a long term functioning society to manage this nascent 4th industrial revolution, without unrest and social upheaval.

Ponder for a second on any investment you make in a manufacturing business. The following are likely to be true:

Somebody has to research the market

Somebody has to talk to vendors

Somebody has to negotiate and buy it

Somebody has to commission it

Somebody has to programme it

Somebody has to maintain it

Somebody has to load and unload it during the shift

Somebody has to change the kit over or update the programme/parameters

Somebody has to respond to it when the Andon goes off

Somebody has to act on that

Somebody has to interpret the data that comes out of sensors

Somebody has to troubleshoot

Somebody has to problem solve and…

…a number of people have to find kaizen to keep you competitive.

‘Somebody’ might be multiple people for each of these activities. What is clear is that ‘Somebody’ needs to considered alongside the physical and data innovation that Industry 4.0 has to offer. InterAct are, comfortingly, working in that space.

This raises an important question about where manufacturers should invest in digital manufacturing. Investment always warrants head scratching as capital dollars/pounds/euros and yen are scarce, but thinking is free. The mantra I’d advise you to adopt underpins the model below. Invest where you SHOULD, not just where you CAN.

This requires pausing, thinking and coming to the CapEx table with a business problem to solve – low productivity or persistent specific quality issues for example. Having said that, the lean start-up principle of creating proof-of-concepts means we can place multiple bets (run trials) on various technologies, as long as we treat them like little experiments to learn whether they’re worth investing in further.

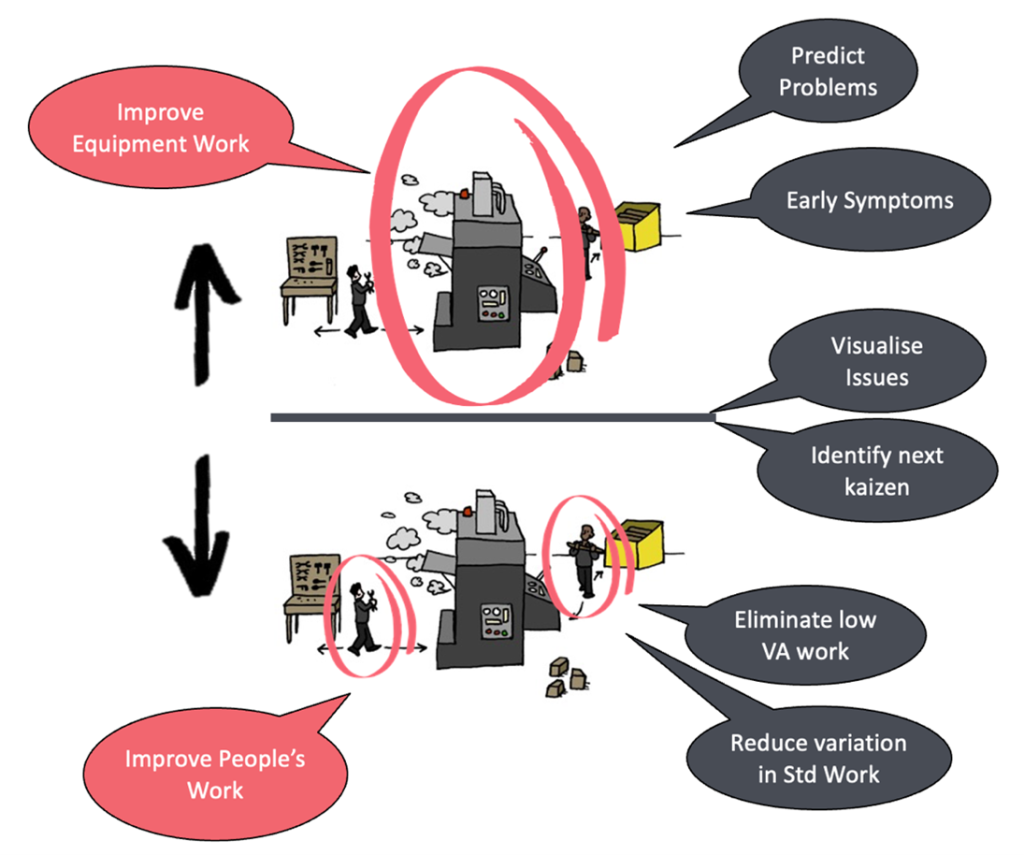

A smart way of thinking about all of this is the Toyota style thinking that I experienced on my last two trips to Japan. They think of it as a numerator and a denominator. The numerator represents the equipment you use to create value that your customers will buy. The aim is to improve the equipment work. The denominator represents the people working in the manufacturing business and asks whether we can improve people’s work.

Within this model, the categories to invest time and resources in are those that:

For the Equipment – “predict problems” or detect “early symptoms” of problems (both of these are likely Safety, Quality or Delivery related)

For the People – “eliminate low value added work” (like walking around checking things at the start of the shift or the admin burden of logging results/performance) or “reduce variation in standard work” (as an example, think 2 setters on opposite shifts changing the same machine from part A to part B, but the first setter takes twice as long)

The real gold to be mined is in the 2 bubbles that serve both. Digital manufacturing done well can “visualise issues” that are hidden to the human eye or our current data harvesting and sensor inputs. Rather nicely, if you listen hard enough to the data, it can identify the next, best kaizen to take you forward.

The idea is this; if you focus on both Equipment and People you’re going to open up a bigger benefit by improving both the numerator and denominator. That sounds very much like competitive advantage to me. As Eddie Jones (yes, the former England Rugby coach) said in his recent book on Leadership “The only reliable advantage we’ve got is to learn faster than the opposition”

InterAct is the best game in town, looking into the future to secure the role of human skill in our bright digital future. Get involved, you can either snooze your way to 2040 and then stand, blinking into the sunlight, complaining about the outcome. Or you can help shape and secure the UK’s place in manufacturing’s coming world order. Interact is moving into an exciting phase in 2023/24 where the research bears practical fruit. There are various ways to get involved, and you can keep up to date with all the latest news and opportunities here.

For more information about Sempai and the support they provide to employers, please click here.