Nikolai Kazantsev (IfM, University of Cambridge), Oleksii Petrovskyi (National University of Kyiv-Mohyla Academy), Julian M. Müller (Seeburg Castle University, Austria and Erfurt University of Applied Sciences, Germany)

Introduction

The term ‘ecosystem’ is derived from biology, capturing a system of entities interacting and depending on each other and reacting to outside challenges and requirements. Business ecosystems represent the intense relationships between interlinked multilateral, complementary actors or partners interacting for value creation (Adner, 2017; Hannah and Eisenhardt, 2018).

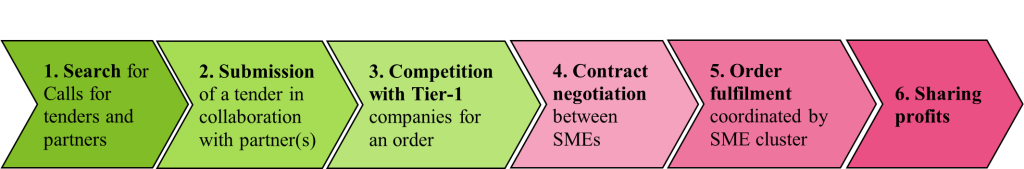

We define a manufacturing ecosystem as a subclass of business ecosystems where supply chain firms arrange demand-driven collaboration in all directions (e.g., with partners, buyers, and even customers), thus competing with large Tier-1 firms for direct manufacturing orders, gaining these orders, fulfilling them and capturing profits. This changes the topology of a hierarchical supply chain into a distributed manufacturing ecosystem, where Tier-1s do not arrange subcontracting of the awarded orders.

In the conventional supply chains, Small- and medium-sized enterprises (SMEs) represent most suppliers worldwide, accounting for 70% of jobs and generating up to 60% of value added (OECD, 2017). For example, the aerospace supply chain starts with the OEM, which places orders in a ‘Calls for Tenders’ (CfTs), organizes tendering processes (often leading to Tier-1s) and awards orders to the team that best matches the requirements. In this industry, SMEs can potentially provide components and services at multiple supply chain levels, but they often miss the scale, scope, standardization or technologies to play a more active role in tendering (Müller et al., 2018). Also, SMEs have reduced ability to act as suppliers due to powerful Tier-1 companies (Schirrmann & Drat, 2018).

However, what if demand-driven collaborations between SMEs are supported?

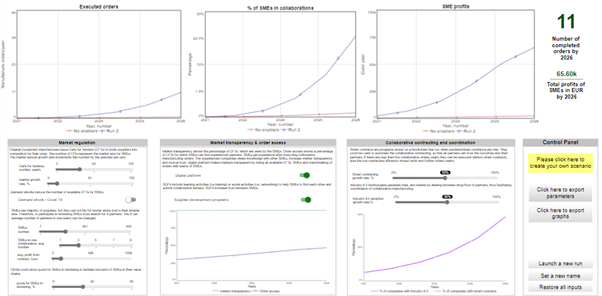

We simulate the application of Industry 4.0, Digital platforms, Smart contracts, and Supplier development programs (Kazantsev et al., 2022) and explore the growth of the manufacturing ecosystem from a conventional supply chain. We used system dynamics to simulate these changes and provide insights for manufacturing firms and policymakers about the desired level of support (Sterman, 2000; Akkermans and Wasserhove, 2018).

An interactive dashboard has been developed that allows the testing of ecosystem development:

Findings

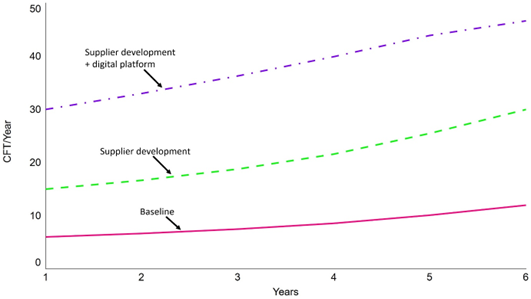

1. Supplier development and digital platforms make marketplaces more transparent so that SMEs can see more calls for tenders

Supplier development programmes and digital platforms are needed to help SMEs identify more calls for tenders and potential partners for collaboration.

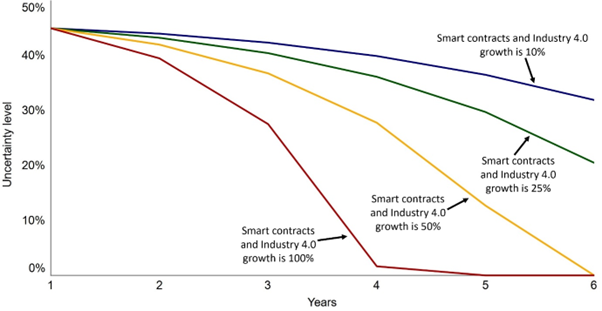

2. The collaboration experience and smart contracts reduce uncertainty levels and enable SMEs to submit more collaborative tenders

Participating in tendering would also enable SMEs to learn how to fulfil orders; therefore, allowing some quotas is helpful. The more firms collaborate on tenders, the lower the level of uncertainty in the market. New technologies, such as smart contracting, indirectly increase the number of submitted tenders and further support the development of a trustworthy business environment.

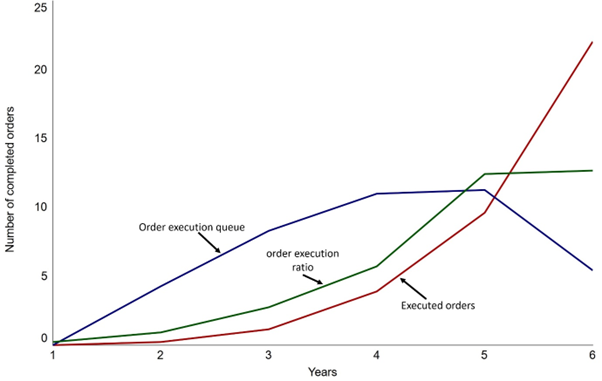

3. Technological support for contracting and coordination reduces the order execution queue and supports the growth of a manufacturing ecosystem

Insufficient contracting and coordination reduces order fulfilment efficiency and calls for digitalization (Kazantsev et al., 2023). Adopting smart contracting and Industry 4.0 increases the ability of SME collaboration to execute the awarded orders in time. Specifically, if we double investments into smart contracting and Industry 4.0 every year, the number of delayed orders grows until the 5th year but then starts falling. In the 6th year, 48 calls for tenders will be available (with a 15 % quota), seven orders out of which will be fulfilled the same year, and six orders from the previous year’s queue. In this case, the order execution rate reaches a plateau – executing all awarded orders. Year 5 is a breakeven point when order execution rate, delayed, and executed orders intersect.

Study implications

Demand-driven collaborations play a critical role in unfolding manufacturing ecosystems. In the early stages of such transitions, investments in collaboration enablers are critical to support ecosystem growth. Thus, we recommend:

- investing in supplier development and digital platforms as early as possible

- enabling quotas for SMEs in tendering

- increasing digitalization of contracting and coordination to support the efficiency of demand-driven collaborations

https://doi.org/10.1016/j.techfore.2023.122917

References

Adner, R. (2017). Ecosystem as Structure. Journal of management, 43(1), 39-58.

Akkermans, H., & Van Wassenhove, L. (2018). A dynamic model of managerial response to grey swan events in supply networks. International Journal of Production Research, 56(1-2), 10-21.

Hannah, D. P., & Eisenhardt, K. M. (2018). How firms navigate cooperation and competition in nascent ecosystems. Strategic management journal, 39(12), 3163-3192.

Kazantsev, N., Petrovskyi, O., & Müller, J. M. (2023). From supply chains towards manufacturing ecosystems: A system dynamics model. Technological Forecasting and Social Change, 197, 122917.

Kazantsev, N. (2022). Supporting SME Collaborations in Low-Volume High-Variability Manufacturing. United Kingdom:The University of Manchester.

Kazantsev, N., Pishchulov, G., Mehandjiev, N., Sampaio, P., & Zolkiewski, J. (2022). Investigating barriers to demand-driven SME collaboration in low-volume high-variability manufacturing. Supply Chain Management: An International Journal, 27(2), 265-282.

Kazantsev N., DeBellis, M., Quboa Q., Sampaio P., Mehandjiev N., & Stalker I. (2023). An ontology-guided approach to process formation and coordination of demand-driven collaborations, International Journal of Production Research, DOI: 10.1080/00207543.2023.2242508

Müller, J. M., Buliga, O., & Voigt, K.-I. (2018). Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technological Forecasting and Social Change, 132, 2-17.

OECD. (2017). Enhancing the contributions of SMEs in a global and digitalized economy.

Schirrmann, A., & Drat, C. (2018). D6.1: Collaboration rules & procedures specification. Retrieved 16.12.2021 from https://6c97d07e-2d66-4f14-9c19-8c5872c4c3ba.filesusr.com/ugd/

2512a7_da7dba0ebb164182803d70e03fe6773b.pdf

Schmidt, M. C., Veile, J. W., Müller, J. M., & Voigt, K. I. (2023). Industry 4.0 implementation in the supply chain: a review on the evolution of buyer-supplier relationships. International Journal of Production Research, 61(17), 6063-6080.Sterman. (2000). Business Dynamics: Systems Thinking and Modeling for a Complex World McGraw Hill.